|

Making a Biofuel: In Brief

1. Pretreatment

• Open fiber

• Increase water access

• Enzyme accessibility

• Degrade hemicellulose

2. Hydrolysis

• Degrade polymers

• Liberate sugars

• Handle viscosity

3. Fermentation

• Conversion of sugars

• Handling of residual fibers

(“Novozymes | Fuel”)

|

|

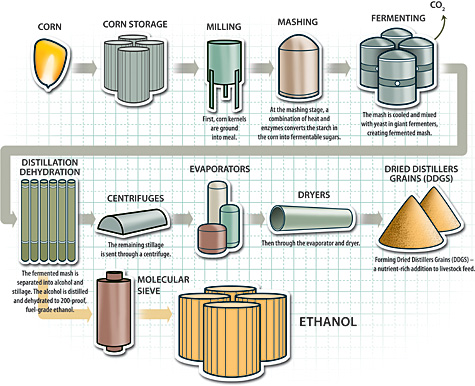

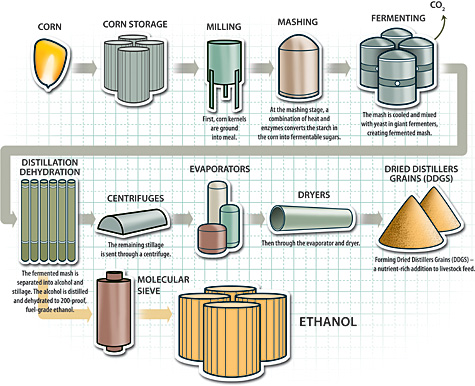

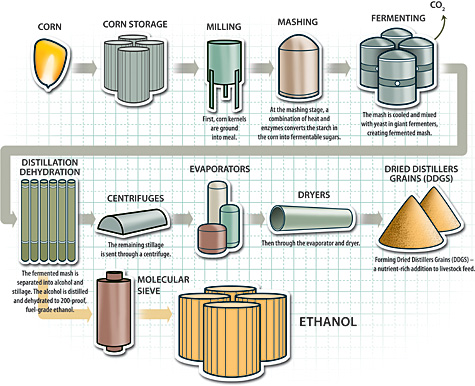

First-generation

biofuels are …

·Produced

through the fermentation of either

starch-based or sugar-based food products such as

corn kernels or

sugar cane into ethanol.

OR

·Processing

vegetable

oils, such as soy, rapseed, and

palm into biodiesel.

Second-generation

biofuels are …

·Considered

more advanced as

they are made from non-food sources.

·Low-carbon,

renewable

fuels that can meet the world’s transportation needs.

·Made

by

converting cellulosic biomass, which is often regarded as waste

material,

into transportation fuels. These include:

·Agricultural

wastes (corn stalks and

husks)

·Forestry

wastes (wood chips and tree

trimmings)

·Fast-growing

trees and grasses

·Waste paper

·Food

processing wastes

("Biofuels |

Energy")

|

|

|

|

Making a Biofuel: In depth

The first method is the batch method, which is the most ensures the fuel is clean for how it is made.

1. Remove water from the oil

2. Thoroughly mix anhydrous solution with alcohol such as methanol, with lye as a catalyst.

3. Let oil sit for several hours so it can settle over low heat. This causes the glycerin in the oil to settle into the bottom of the tank.

4. Remove alcohol from the mixture and purify it through washing.

5. Now, the mixture is ready to be stored and used.

The second most popular way of production biofuel is called the Supercritical Biodiesel Production process. The entire process must be done over high heat levels.

1. Follow the batch method except use supercritical alcohol is used instead of regular alcohol, which makes the entire process used in the batch method happen much faster.

2. Also, in this process, the removal of the alcohol is not necessary.

Note: This method is not as popular as the batch method, because the energy costs associated with producing biofuel in this manner are much higher, since the entire mixture must be done at high heat from the start of the process to the very end.

The third method used to make biofuel is called the ultrasonic reactor method.

1. Use ultrasonic faves throughout the mixture to separate it and produce the biofuel.

Note: This reduces the length of time which is required to make the fuel, and it also allows for larger batches of biofuel to be made. This is the most common method used in industrial situations, as it allows for huge batches and is very cost effective. Hopefully, this will become the cheapest way for biofuels to be produced.

The last method is the microwave method

1. Use a microwave oven to bring about the chemical reaction in the oil.

2. Use higher temperatures to allow the oil to get processed much faster and at less energy rates than the other methods discussed

Note: This method is not widely used as it is still being researched as a possible means for mass production of biofuels. Even though the method is rather new, it is very plausible that it might become the preferred method of producing biofuels in the future.”

(“Biofuel Production”)

|

|